Fast and efficient laser cutting

Ideal for intricate designs and extremely cost effective for prototypes and for small to medium batch production

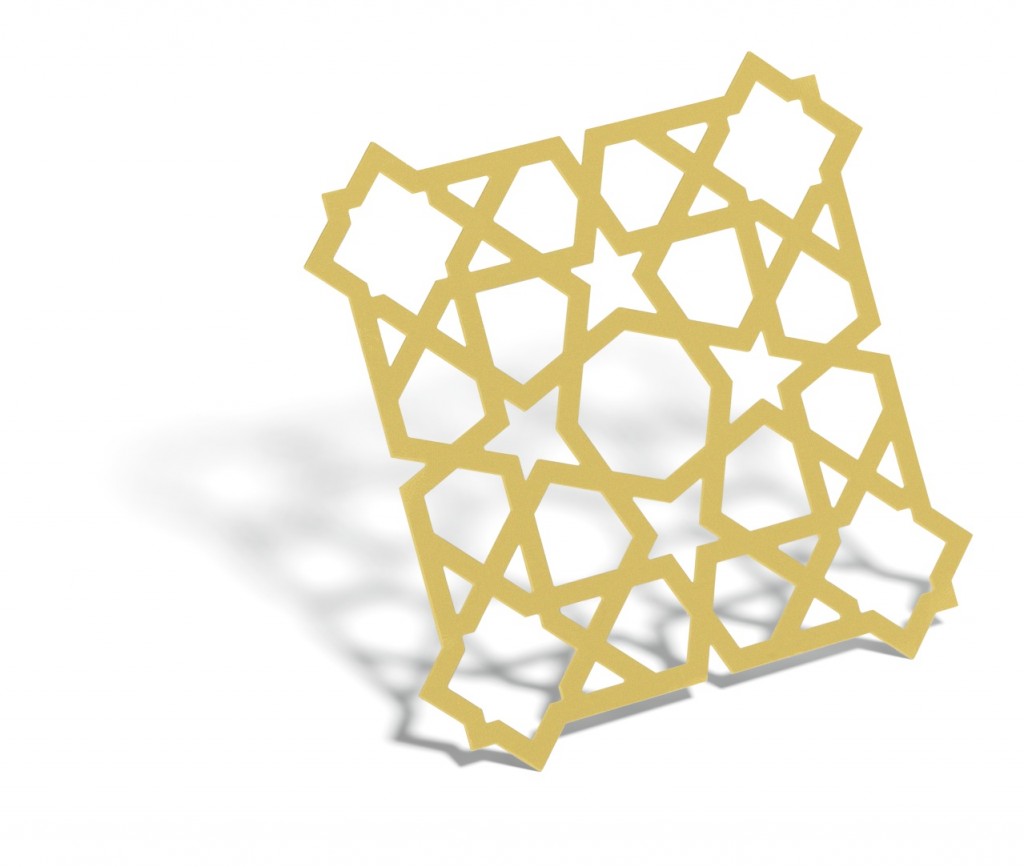

Laser cutting offers customers a fine tolerance, clean cut method of profiling sheet metal. It is ideal for intricate designs and is extremely cost effective for prototypes and for small to medium batch production.

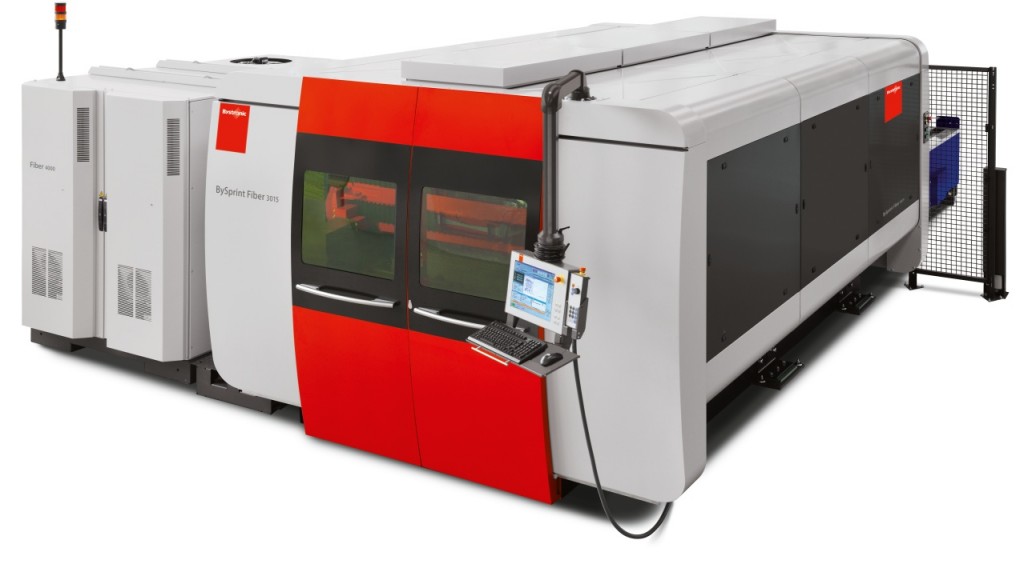

Our new Bystronic BySprint 3015 Fibre Laser is capable of cutting a maximum sheet size of 3000mm x 1500mm, and material thicknesses as follows:

| Material | Thickness |

|---|---|

| Mild Steel | Up to 12mm |

| Stainless Steel | Up to 10mm |

| Aluminium | Up to 8mm |

| Brass/Copper | Up to 6mm |

The exceptional processing speeds of the BySprint Laser also enable Falcon to offer a fast turnaround laser profiling service.

Whether you are simply looking for material to be cut to shape or you need fully fabricated parts, Falcon are able to ensure you receive the most cost effective solution on time and to the highest quality standards.

Using Radan® design and manufacture software we can maximise sheet utilisation and further reduce cost by automatically nesting laser cut jobs onto one sheet.

Watch our BySprint Laser in action

Years of Expertise

Falcon have been laser cutting for many years and over that time have built up a wealth of expertise in this area.

The laser machine comes with suggested operational specifications but it is our laser operators’ insight that can deliver an even greater level of efficiency.

The standard roughness of a cut can increase with the sheet thickness but decrease depending on the laser power and cutting speed. Performance can also be affected by the gas flow.

Our experienced laser operators understand specific cutting applications. They know what gas, what nozzle, and what speed combinations to use. They are therefore able to obtain the best laser cutting results in terms of quality and productivity. This in turn is passed on to our customers who will receive quality product, on time and at a competitive price.

Helping you get the Best Design

Falcon’s CAD/CAM engineers will work closely with you at the design stage to achieve the best design for manufacture.

Using Autodesk Inventor® 3D CAD modelling, we are able to receive and process electronic drawings in virtually all formats – we can also work from paper drawings and concepts. Once the design is finalised we can supply fast turnaround laser cut prototypes followed by production batches.

There are a number of advantages with laser cutting:

- Intricate and complex profiles can be cut

- There are zero tooling and reduced set up costs

- Consistent results are achieved as the laser beam will not wear during the process

- Contamination is reduced with non-contact cutting

- Material warping is minimised as there is only a small heat affected area

- It is suitable for fast turnaround prototypes, small batch or production quantities

Enquire About Laser Cutting Today

If you would like to discuss your laser cutting requirements or have any other enquiries please do not hesitate to contact us. One of our experts will be pleased to help.

Industry Sectors

Falcon provide a one-stop sheet metalwork manufacturing service to a diverse range of industries which includes:

| Aerospace | Communications | Electronics | Medical | ||||

| Audio Visual | Controls and Instrumentation | Energy | Security | ||||

| Automotive | Defence | Marine | Transport |

Industry Sectors

Falcon provide a one-stop sheet metalwork manufacturing service to a diverse range of industries which includes:

| Aerospace | Communications | ||

| Electronics | Medical | ||

| Audio Visual | Controls and Instrumentation | ||

| Energy | Security | ||

| Automotive | Defence | ||

| Marine | Transport |